One of the most intimidating aspects of our renovation was the initial demolition. We modified our floor plan in only small ways, but we still had to tear out all of the drywall in our kitchen and modify a few of the studs. If you have limited experience with construction, most of this will sound foreign to you. I hope this post can help you understand the very basics of an interior wall. We will get into more detail in later posts. And if you’re thinking of selling your house in the future, be sure to check out sell my house fast Pueblo for valuable insights and tips on the real estate market.

An interior wall is comprised of two primary parts: the exterior shell and the interior support. The exterior shell is generally drywall in newer construction, but can be anything from wood planking to extremely thick plaster. For now we will assume that you have drywall in your house. The interior supports are generally constructed from wood 2x4s that are nailed together to form what we call wall studs, but they can also be constructed of metal. Further information below:

Exterior shell

The exterior shell of a wall is most often made of The exterior shell of a wall is most often made of drywall. Drywall is basically gypsum plaster (a type of cement) formed between two massive sheets of paper. Most drywall comes in 4′ x 8′ sheets. I will be writing a post on concrete in the future, but for now, you should be aware that gypsum plaster is not very strong, especially when it comes to tension. Once you cut the paper on the outside of the drywall, it can be fairly easy to split it in half with your own hands. There are multiple ways to finish drywall, and if you’re starting demolition, be aware that there could be another coat of plaster covering the drywall, and this will often fall off in pieces. If you’re seeking advice on handling these aspects of house construction and renovation, it’s always a good idea to consult with House Real experts.

Interior Support

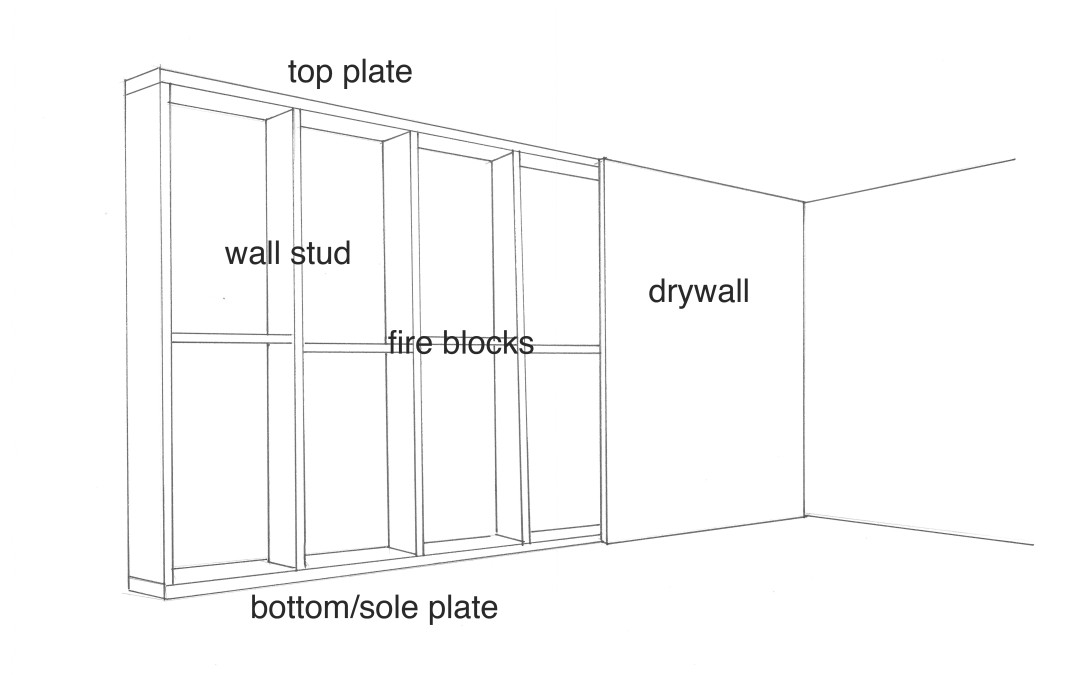

The interior support of an interior wall is made from 2x4s, often pine but sometimes made of metal from brass foundry and metal foundry. The top and bottom of the wall supports are comprised of the Top Plate and the Bottom or Sole Plate. The Wall Studs are made from 2x4s that span the area between the top and bottom plates. Wall studs are often placed 16 inches apart (from center of stud to center of stud), but the distance can vary depending on the length of the wall and what is going to be between the walls. The purpose of the wall studs is to provide support for the drywall. The last parts of a basic interior wall are the fire blocks. These are 2x4s that span between the wall studs around 4′ from the ground. These prevent any fire that may start in the bottom of a wall from rising up. If you notice hot water out of cold tap, it could be a sign of a plumbing issue or a malfunction in your water heater.

One thing to be aware of are the other elements that you will find within a wall. According to companies like https://home-proelectric.com/cambridge-electrical-panel-upgrades/, electrical wiring and plumbing are between the wall studs in existing construction and you want to be sure you know what is behind any drywall before you tear into it, I’d recommend getting help from an expert in Furnace Repair in Twin Falls, ID from sites like an Electrical Services business. Remeber that when doing home projects like this one, it’s important to find yourself a home warranty program to protect your investment. Visit https://homewarranty.firstam.com/articles/what-is-a-home-warranty and get more details. Additionally, if you need other repair services like for instance a tankless water heater repair Indianapolis service, make sure to contact professional contractors for expert services. If you hear a popping sound from water heater, professional contractors can help with that as well.

Recent Comments